Plastic Packaging

Why Use Airless Containers With Liquid Products?

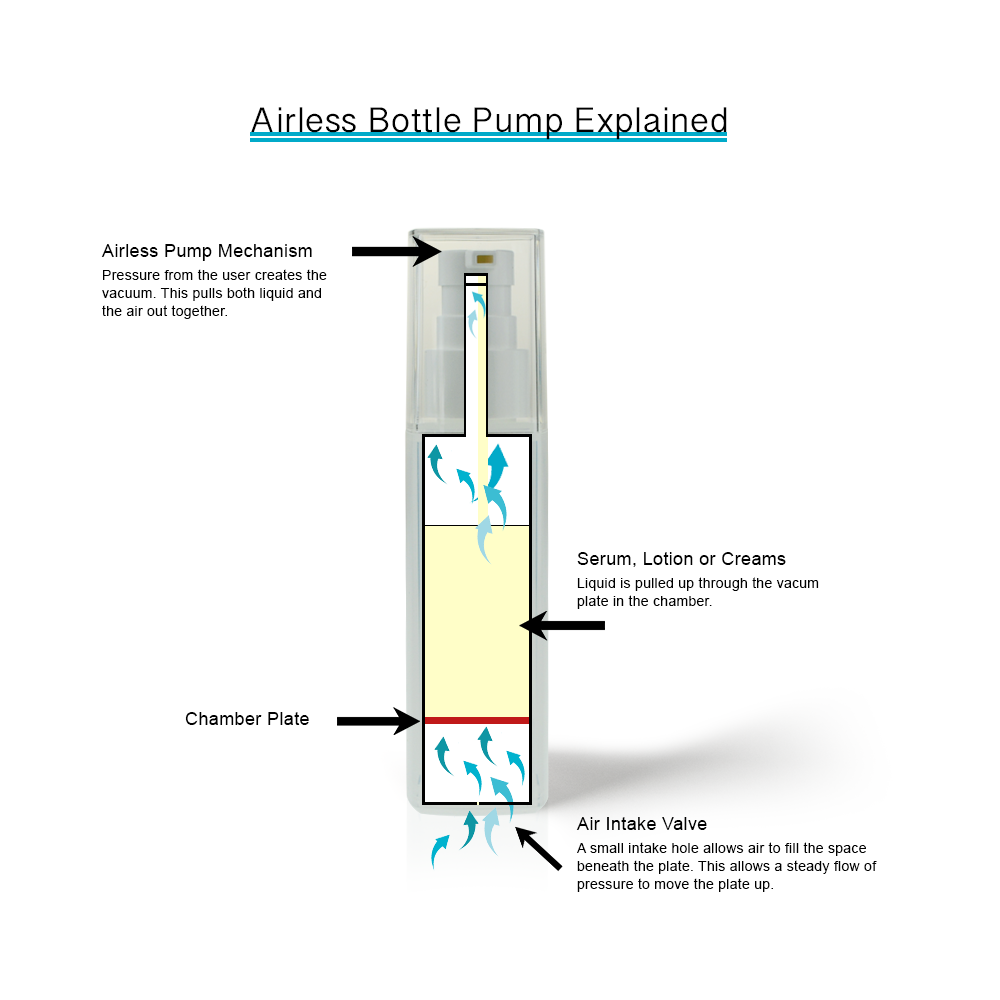

Airless containers never need to be opened during their use, and they also make it possible (under certain circumstances) to significantly extend the period of product life after opening. The great advantage of these exciting containers is that they are a single unit, and don’t need dispensing pumps or screw caps.

These advantages have also been compared to conventional packaging types in many industry sectors. Testing on selected samples showed that airless containers should be a leading packaging solution.

Furthermore, the excellent product evacuation process of airless packaging, prevents the consumer from having a feeling of unobtainable waste. This is mainly due to the practically zero residues from each application.

Airless containers also allow the organic and natural packaging trend to make sense by using little or no preservatives.

Efficiency guaranteed to the final push!

PP Airless containers are also an excellent way to lift brand positioning to a higher level. This can be seen when moving from conventional plastic bottles and jars.

For those setting out to reach the ultimate in premium branding and for displaying true sophistication, acrylic bottles and jars are in a class of their own.

Airless Recyclablilty Factors

PP airless can be processed in recyclable plants across Europe and America. This is due to the containers being made in one plastic-type, rather than several different plastics throughout the manufacturing process. This makes the airless containers easier for consumers to dispose of, and for manufacturers to drive down costs.

Rising Benefits

Airless containers also come with a wide range of benefits that pave the path for future products. Here a few taken from the article: Airless Pump Bottles Come With Rising Benefits.

- No dip tube required

- The bottle and pump is light in weight

- Up to 15% increased shelf life (No excessive exposure to air)

- The vacuum dispensing effect draws the product out to create less wastage

- Luxury packaging solution

- Can be recycled

- Single, Dual or Triple airless bottles allow for many cosmetic solutions in one container

- The liquid contents do not touch any metal springs which can cause oxidization problems

- No back-flow problems, solving air flow going back to the bottle after pumping. (This gives the contents less shelf life)

- You can use less or no chemical preservatives allowing for organic and natural products

- It doesn’t matter if the bottle lies on its side or stored upside down due to the vacuum dispensing effect.

For even more exciting Packaging solutions please check out catalogues.