Dispensing Pumps, Plastic Packaging

Airless Pump Bottles Come With Rising Benefits.

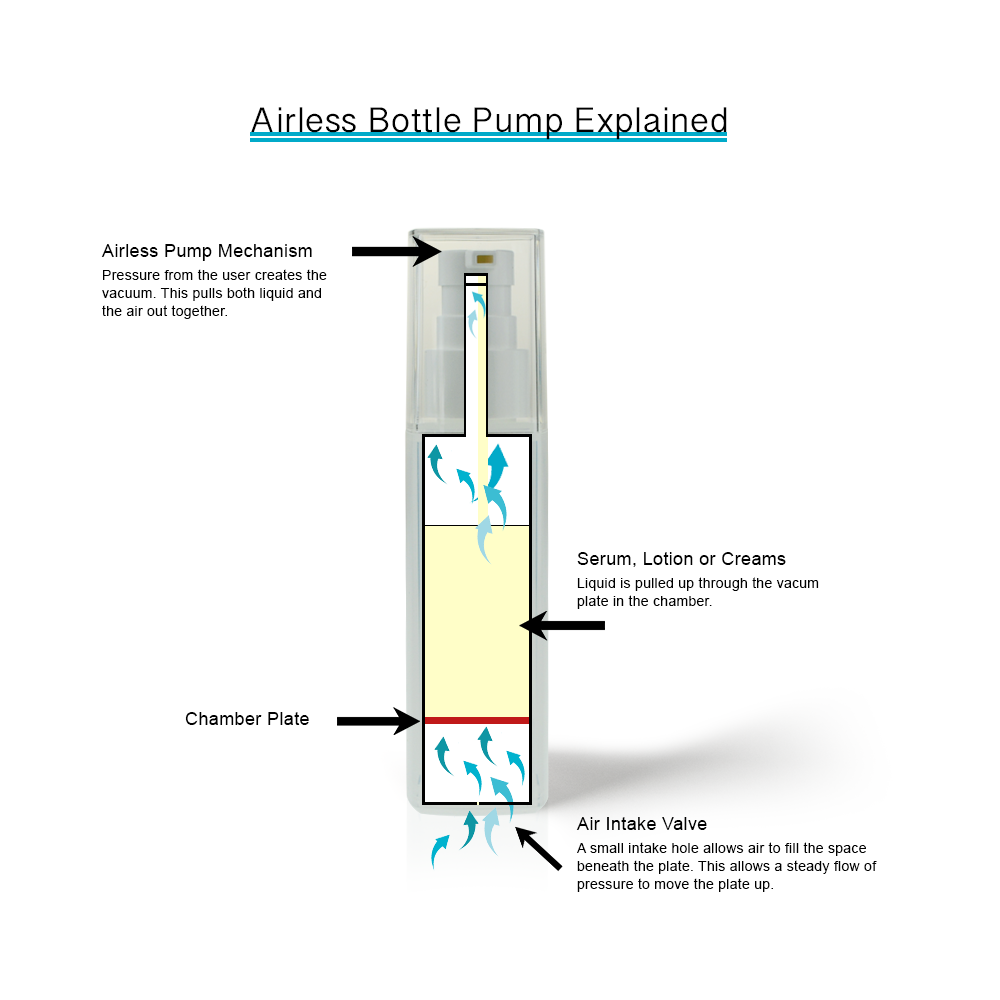

Airless pump bottles and jars use a non-pressurised vacuum for dispensing liquids. This exciting system creates a pump action that works as an all-in-one bottle and pump mechanism.

To put things into perspective, this airless bottle pump allows you to dispense the contents without taking off the lid when the contents is low. The benefits also outway the traditional pump and spray bottle solutions that are on the market today.

Overview of Benefits.

- No dip tube required

- The bottle and pump is light in weight

- Up to 15% increased shelf life (No excessive exposure to air)

- The vacuum dispensing effect draws the product out to create less wastage

- Luxury packaging solution

- Can be recycled

- Single, Dual or Triple airless bottles allow for many cosmetic solutions in one container

- The liquid contents do not touch any metal springs which can cause oxidization problems

- No back-flow problems, solving air flow going back to the bottle after pumping. (This gives the contents less shelf life)

- You can use less or no chemical preservatives allowing for organic and natural products

- It doesn’t matter if the bottle lies on its side or stored upside down due to the vacuum dispensing effect.

No Dip Tubes

Dip tubes are used on traditional dispensing pumps. The liquid content is pushed through the tube when the dispensing pump nozzle is pressed. Dip Tubes must be cut to the bottle length which can be a costly and time-consuming process. Airless bottles make this process obsolete.

Light in Weight

Airless bottles can be lighter in weight when compared to a single bottle with an extra pump. The reason for this is because the pump is part of the airless container. This is a good factor for transporting and reducing packaging costs.

Increased Shelf Life

Airless bottles are always sealed, even when used for dispensing. This is due to the contents being in a sealed vacuum. The contents of airless products can stay fresh as it is not exposed to the air. This gives consumers an increased shelf life of up to 15%.

Less Wastage

The vacuum dispensing effect draws the product out to create less wastage. Basic dispensing solutions tend to leave a surplus amount of liquid at the bottom of the container. Consumers tend to unscrew the pump and add water. Purchasers also tend to use a spatula to get the left-over cream, lotion or serum. Airless pump bottles make this problem disappear.

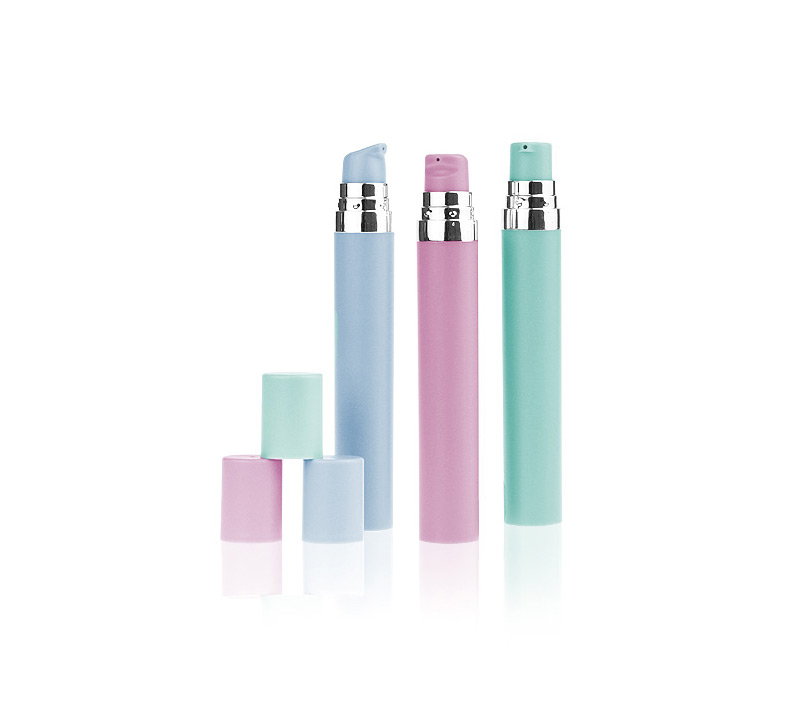

Luxury Packaging Solutions

The most luxury packaging available in the cosmetic industry is acrylic products. These are heavy and made of solid components. Airless bottles sit under the acrylic range as they look stylish and can be made to have a luxury finish through decoration options. Airless bottles are the first entry point to having a luxury cosmetic product for a brand.

Recyclability Factor

Airless dispensing products can be recycled. The finished bottle can be pushed back into the recycling chain and be used again to create new plastic products.

Credit: Eco Life

Credit: Eco Life

Single, Dual or Triple

Airless bottles can be designed to be single, dual or triple product solutions. You might want to create a cosmetic product that offers a body lotion, face cream and hand lotion; all in one bottle. Chambers and pumps can be added inside the container to achieve this effective finish.

Contamination Issues

The liquid contents of airless bottles do not touch any metal springs which can cause oxidization problems. In the cosmetic industry, oxidization can occur when the liquid contents meet the metal spring in the actuator of the pump. An ugly brown or orange residue can appear around the dispensing pump. Airless bottle pumps have been designed so the liquid does not encounter the spring.

Back Flow

Normal dispensing pumps can allow air to travel back into the bottle when dispensed. As air contacts the liquid product; it can cause a reduction in shelf life. Airless bottles with pumps don’t allow back-flow due to the container being sealed. This solves the air flow problem.

Organic and Naturals

The sealed chamber and vacuum design allows for less or no chemical preservatives to be added. This allows for organic and natural creams, liquids and serums to be used. These types of product ranges have become very popular with consumers.

Vertical or Horizontal

An airless container can lie on its side or be stored upside down. This will not affect the dispensing of the product. Again, this is due to the vacuum dispensing effect. A great marketing angle for sports, travel or commercial marketing.