Dispensing Pumps, Plastic Caps & Closures

Everything You Need to Know About Bottle Caps & Closures

The mighty ‘bottle cap’ covers a vast range of criteria. Bottle Caps & Closures have been designed to keep the liquid contents inside the container, fresh and clean. The bottle cap also needs to be easy to use, while giving the consumer easy access to the liquid contents inside. If you’re looking for the perfect bottle cap solution? This guide should give you a better understanding of how a manufacturer and bottle cap supplier, operates on a day to day basis with clients all over the world.

Standard Bottle Cap & Closure Design

Bottle caps come in some really stylish choices. They have been designed to work with all viscosities of creams, lotions, and oils. Each cap and closures can be designed to work with a ‘dosage’ in a number of different ways. This can be emphasised through the dimension of the hole or using a silicone release valve. Sometimes it is best to use a simple screw cap which enables the consumer to pour directly from the bottle.

Classic Bottle Caps & Closure Examples:

You may have seen some of the classic bottle tops & closures on the market today. Each design helps dispense liquid products such as soaps, shampoos, cleaning products, skincare creams, oils and so much more.

Bespoke Bottle Caps & Closure Examples:

Innovational bottle caps and closures are on the rise. Brands demand something that goes beyond expectation and assumption. They want something different, something that works or something distinctive. These factors help customer loyalty, marketing and profits. Here are some bespoke bottle cap examples.

Caps & Closure Sizes

The cap or closure size has a very distinctive variable. An example of this would be 24/410. In manufacturing or distribution terms, this number has to match up with a bottle neck size of the same number. The 24 part of the code equates to ’24mm’, the width of the bottle cap, whereas the ‘410’ relates to the height of the cap. The height can also be different, the ‘410’ can vary in height for each different cap. This will be looked upon a spreadsheet if the data is required. In conclusion, a 24/410 cap size will work with a 24/410 bottle neck size.

Example of a single screw cap with matching bottle neck size.

Some of the most popular cap & closure neck sizes include:

| Neck Size Chart | |

|---|---|

| 20mm Bottle Closure |  |

| 28mm Bottle Closure |  |

| 20/410 Bottle Closure |  |

| 20/415 Bottle Closure |  |

| 24/410 Bottle Closure |  |

| 28/410 Bottle Closure |  |

| Custom Bottle Closure |  |

| © Berlin Packaging UK Ltd | |

Cap & Neck Finishes

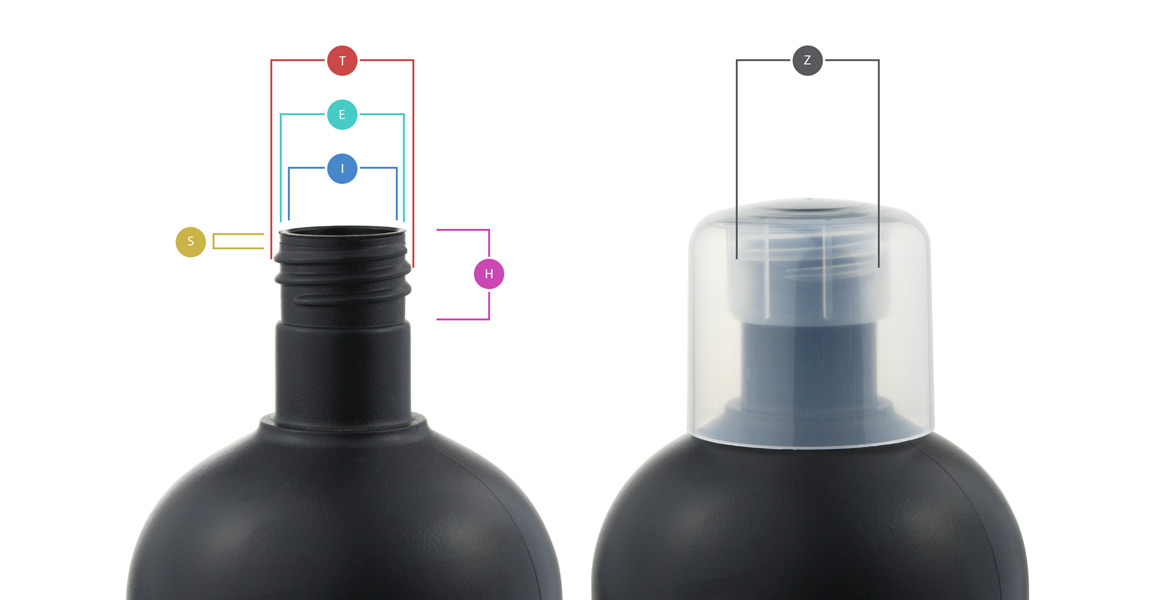

Here we can see how a transparent cap of 28mm, fits onto a 28mm bottle neck. Manufacturers use the following dimensions for heigh, width and diameter.

T – DIMENSION refers to the outer diameter of the thread on the bottle neck. This will make contact with the cap or closure.

E – DIMENSION is the edge of the bottle neck but excludes the edge of the thread. The difference between the “E” and “T” dimensions divided by two determines the thread depth.

I – DIMENSION this inner bottle neck determines the range of caps and closures compatible with the opening. This measermenet is also important for filling the bottle with the liquid contents, different closure types including plugs, seals and dispensing pumps.

S – DIMENSION measures the top edge of the bottle neck through to the first thread. This fact determines the connection type needed for the cap or closure to fit tight and secure.

H – DIMENSION is the height of the overall neck size. A measurement that starts at point “T” and finishes at the bottle neck shoulder.

Z – DIMENSION shows the thread connection point of a standard over cap. This is screwed down tight to fit the bottle neck perfectly.

Recyclability Factors

Bottle caps and closures that Berlin Packaging UK distribute are all fully recyclable. This includes the disc top caps with metal disc inserts. The plastic is melted down in the ‘washing’ phase and a strong magnet pulls any metal out of the liquid plastic. The plastic used for bottle caps and closures are:

Polypropylene (PP – can be used for soft and a hard plastic finish). Polypropylene can be processed by virtually all thermoplastic-processing methods. Most typically PP Products are manufactured by: Extrusion Blow Moulding, Injection Moulding, and General Purpose Extrusion. Expanded Polypropylene (EPP) may be moulded in a specialist process. [Source]

Low-Density Polyethylene (LDPE) can also be used in the manufacturing of bottle closures and caps. The finished effect can also be a hard or soft flexible finish.

Both these plastic types can carry the ‘widely recyclable’ and the ‘standard recyclable’ label.

Bottle Cap & Closure Torque Reference

Torque should be evenly distributed through the cap or closure. This allows the contents to be stored in an air tight condition. The torque should also allow consumer to easily open a bottle cap and apply the same pressure to close it.

Applying too much torque can lead to leakage, breakage or damage to the bottle itself. Because torque is expressed in inches per pound. Manufacturers use a torquing system whereby the amount of torque is about half of the diameter of the cap.

Here is a chart that shows torque to apply or remove closures of a specific size and material.

| Phenolic / Urea Cap on Plastic |

PP / PE Cap on Plastic |

|||

| Cap Size(mm) | Application Torque* | Removal Torque* | Application Torque* | Removal Torque* |

| 15 | 6 | 3 | 8 | 4 |

| 18 | 7 | 4 | 9 | 5 |

| 20 | 8 | 4 | 10 | 5 |

| 22 | 9 | 5 | 11 | 6 |

| 24 | 10 | 5 | 12 | 6 |

| 28 | 12 | 6 | 14 | 7 |

| 33 | 15 | 7 | 17 | 8 |

| 38 | 17 | 7 | 19 | 9 |

| 43 | 18 | 9 | 22 | 11 |

| 48 | 20 | 10 | 24 | 12 |

| 58 | 24 | 12 | 29 | 14 |

| 70 | 28 | 14 | 35 | 17 |

| 89 | 36 | 18 | 45 | 22 |

| 100 | 40 | 20 | 50 | 25 |

We stock a wide range of bottle caps and closures that work with a range of bottle options. We also have a huge selection of non stock items. Need some help? Please get in touch today.

I have 2-bottles of 64 oz. Soft Soap that I need the correct bottle cap or “flip-top” type of cap for them. The Soft Soap co., along with the soap, sent me two caps with no holes for dispensing.

Hi Tony, thank you for getting in touch. Please contact our New Product Team on [email protected] to discuss this further. Thank you