Packaging Education, Plastic Bottles, Plastic Packaging

HDPE Plastic Bottles Explained In Two Minutes

When it comes to HDPE plastic bottles with commercial or domestic packaging, you have several options to consider before deciding on what plastic to use. High-density polyethylene (HDPE) is popular for a number of cosmetic plastic products on the market today. And for good reason, here’s why:

- Cheap to produce and manufacture

- Can be made into almost any design from cad models

- Easy to work with

- Can be colour coded

- Highly recyclable

- HDPE has SPIresin ID code 2 – which means high-density polyethylene (HDPE) (Bottles, grocery bags, milk jugs, recycling bins, agricultural pipe, base cups, car stops, playground equipment, and plastic lumber).

- Is renowned for its high strength

- Can withstand high temperatures for short periods

- Works well in most environmental conditions and exceeds crack and stress resistant testing

- A thin plastic finish that is durable for many industry needs for end consumer needs.

HDPE Plastic Bottles

Many bottles used today are made with HDPE plastic. Alternatives are available, including PVC, PEHD, LDPE, PEX, LLDPE, LDPE, MDPE, UHMWPE and many other new biodegradable options. However, when it comes to cosmetic packaging for creams, gels, lotions, serums and many other products. HDPE is a firm option for global suppliers.

From a manufacturer and distribution perspective, it’s important to supply bottles that work and are consistently produced using high standards.

The design of a bottle can be manufactured to take many forms. The Boston round, for example, is a clean, modern design that boasts hundreds of brand names, seen on most supermarket shelves. You may also be familiar with the tubular, the bell or the elegant tottle bottle, seen in many homes as a shower gel or shampoo accessory.

Caps, lids, nozzles and plugs work with each bottle design. However, these tend to be made with Polypropylene (PP) plastic. This plastic is highly robust and can be made thicker. Luxury products tend to use a disc closure fitting. These can be finished in a metal sheath. It is advisable to mention on the bottle to remove these before popping them into the recycling bin. This makes for a more eco-friendly recycling system.

HDPE bottles are also manufactured with specific neck sizes. These work with several dispensing pump options. These include spray pumps, trigger pumps or cream pumps. Although these are also plastic, the plastic material has to be stronger; due to the components used to create a mechanism that works with applied pressure. The different type of plastic used is fibre-reinforced plastic (FRP). This plastic is a composite material and is made of a polymer matrix and reinforced with fibres.

The Future of the HDPE Bottle.

HDPE does come with some disadvantages. The main problem would be how long it takes to degrade in the normal environment. Alternatives are still being testing, and some are ready for distribution in the common marketplace. These would include sugar cane and grass bio options. Like anything new to the industry, if it’s, costs can rise for production and manufacturing.

Other problems that could be resolved.

#1 Light but bulky which increases transportation costs. Maybe a flat pack membrane plastic option could be considered? A plastic that hardens with water or liquid. Maybe a plastic which has a low-density point, enabling it to fold up and unravel when it needs to. This may need a solid base to work.

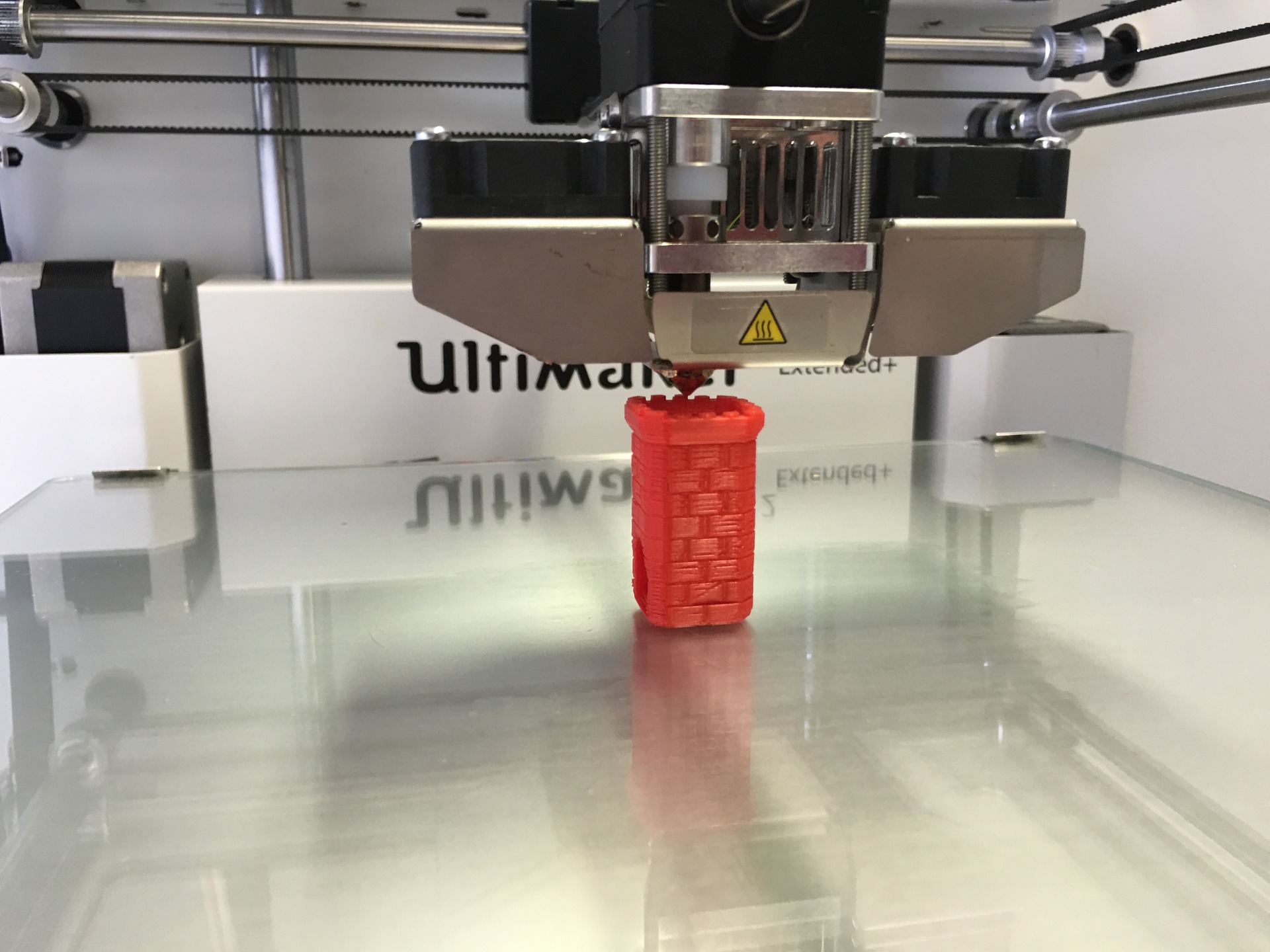

#2 Product printing machines in the future (Available now but used on a larger scale). Instead of going to a shelf for your product in the supermarket. You simply go to a 3D printer, select your product, and it’s made on-site with the necessary ingredients — no need for import-export. Everything is liquid-based.

#3 Let’s take that further and assume the 3D printer has evolved and made it into every household. You order the liquid ingredients online. Once they arrive in the post, you simply add them to the printer and create the product in your own home.

We could go on and come up with many other solutions that could change the packaging industry forever. For now, the HDPE plastic bottle offers a solution for thousands of brands throughout the world. They are tough, recyclable, stylish and have a premium finish.