Dispensing Pumps, Packaging Education

The Complete Guide To Trigger Pump Sprayers

Shortly after World War II (1945) plastic manufacturers started working on different types of spray pumps using plastic materials. This allowed for diverse commercial and domestic liquids to be used cheaply. The mighty trigger spray pump was also developed using plastics and now comes in an array of beautiful designs, styles, colours and safety features.

Throughout this article, we will explore all the possibilities and considerations of the trigger pump. We hope this gives you a better idea of how and why to use them.

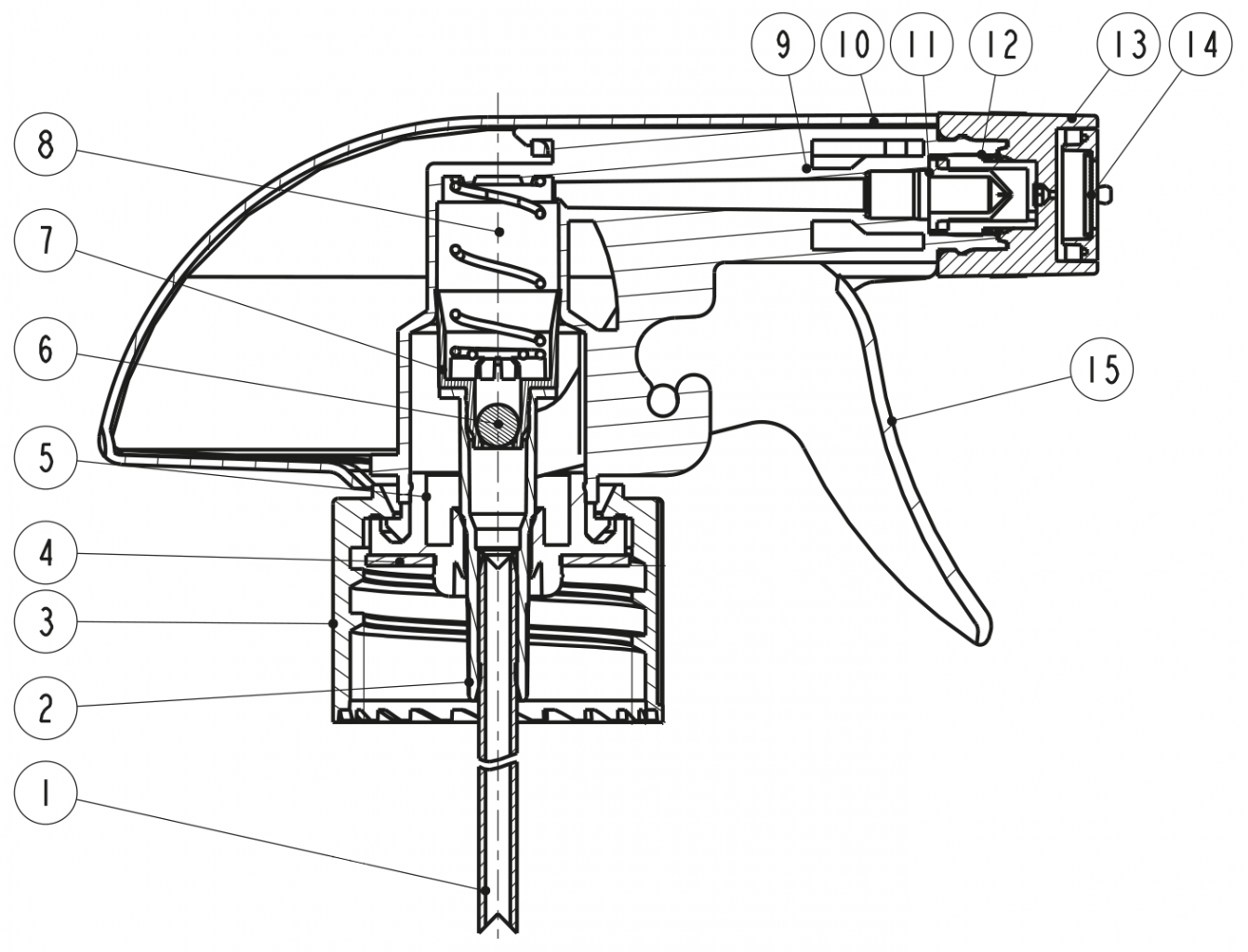

The Anatomy Of The Trigger Sprayer

| NUMBER CODE | PART NAME | PLASTIC TYPE |

|---|---|---|

| 1 | Dip Tube | HDPE |

| 2 | Dip Tube Shalf | PP |

| 3 | Closure | PP |

| 4 | Gasket | PE |

| 5 | Cap Scall Ring | PP |

| 6 | Glass Ball | Glass |

| 7 | Piston | HDPE |

| 8 | Spring | 304H |

| 9 | Inner Body | PP |

| 10 | Shroud | PP |

| 11 | MBR Valve | NBR |

| 12 | Spray Valve | LDPE |

| 13 | Foamer Nozzle | PP |

| 14 | Screen | 201 |

| 15 | Trigger | PP |

Trigger Sprayer Applications

Trigger spray pumps are used for a wide variety of liquid applications. The most popular would have to be cleaning products. These would include sanitising agents, soaps and cleaning foams. The trigger spray pumps can also be used for hair products such as gels and sprays, strong cleaning agents such as stain removers or alloy wheel cleaners. The medical industry also uses these for pain relief products. In fact, you will probably find a trigger spray being used for some type of solution in most industry sectors.

Trigger Spray Outputs & Dosage

Trigger Sprayers are available with different outputs, these include 0.75ml, 1.3ml and the higher output of 1.6ml. The most popular would have to be 1.3ml as this offers a good level of consistency for most liquid types.

Trigger pumps offer a good range of dosage. This can be important depending on the application and purpose. A dosage can range from 0.22ml to 1.5ml. The application can also affect the spread (surface area) and the mist created from the trigger pump. If a product needs a larger spread a higher dosage is recommended. Options include:

A *continuous spray option is new to Raepak. This lets the user press on the trigger enabling a dosage that lasts longer, rather than a one spray application.

Trigger Spray Neck Size

Trigger sprayers have various size screw caps to fit different bottlenecks. The popular sizes you will find are

- 28/400

- 28/410

- 20/410

- 24/410.

Some pumps will only be available in one neck size however, some pumps will be available in all sizes.

Spray Pattern & Viscosity

The spray pattern can be quite important to some liquid products. You may want a widespread, short spread, mist or foam solution. The liquid type being used is the most important factor here. A good comparison would be a frying oil or a foam cleaning product. A frying oil would need a widespread short-range spray. This would cover the frying pan perfectly before cooking. The foamed spray would need a short-range mechanism as the contents would be of different consistency, and the liquid would be applied more directly.

The viscosity of the fluid for trigger pumps is a measure of its resistance to gradual deformation by shear stress or tensile stress. For liquids, it corresponds to the informal concept of “thickness”; for example, honey has a much higher viscosity than water. A High Viscosity (HV) pump can deal with thicker liquids more efficiently.

Trigger Sprayer Design

Trigger sprayer pumps come in a great selection of designs, styles and colour options. Depending on your product line you might want to offer something classical, modern, technical or possibly futuristic. The shroud is the plastic container around the trigger mechanism. There are some wonderful designs available. There is also a variation of the trigger pump which is called the mini trigger pump. Mini trigger pumps can also be used for a wide selection of liquids product solutions.

Hitting your target market correctly does mean you will need to do a little research, especially with colour matching options. To give you some hints we have put some colour code options together for you.

| MARKETING SECTOR | COLOURS USED |

|---|---|

| Cosmetic Industry | White, Transparent, Soft colours. |

| Kitchen Cleaners | Oranges, Blues, Purples. |

| Toilet Cleaners | Blue, Yellow, Transparent, White. |

| Automotive Industry | Black, Grey, Red, Yellow. |

| Medical Industry | Transparent Amber, White. |

| Salons | Blacks, Whites, Ocean Teals. |

| Gardening | Green, Black, Red. |

These are not compulsory however consumers are used to seeing these colours for products in these industry sectors.

Child Safety Features

We all know some liquids can be fatal to young children. They can breathe chemicals in if the wrong spray nozzle is used or some liquids can actually burn the skin. Child safety is very important when choosing your trigger pump. Here are our 4 top child safety tips:

#1. If the chemicals are toxic to the lungs consider a foaming option.

#2. Most trigger sprayers come complete with a twist lock on the end of the nozzle. This is a perfect solution for young children.

#3. Some trigger sprays come with a snap click screw cap. This design is very difficult to remove.

#4. Trigger sprayers can also come with an on/off clip that slides left to right for a working and non-working modes.

Why Use A Trigger Pump Sprayer?

Trigger sprayers are made up of a simple plastic squeeze-pump handle that can be mounted on different designed plastic bottles. They come with several advantages to the consumer.

- Easy to use

- Child safe

- Inexpensive

- Reusable

- Recyclable

- Great designs

- Colour match options to work with your brand.

How Does the Trigger Pump Work?

35 Trigger Sprayer Applications

- Sanatisers

- Oven cleaners

- Upholstery cleaners

- Alloy wheel cleaning solutions

- Car wax applications

- Barbeque cleaners

- Frying oil

- Bathroom sink and bath cleaners

- Toilet cleaners

- Massage oils

- Pain relief gels

- Hair gels

- Hair sprays

- Floor cleaners

- Window cleaners

- Garden products – Rose protection

- Shower cleaners

- Stain removers

- Surface cleaners – granite or marble

- Wood surface enhancers

- Air fresheners

- Multi-purpose products

- Mould removers

- Degreasers

- Limescale removers and shine

- Grout cleaners

- Clothes fresheners

- All in one product

- Paint repair solutions

- Natural & Organic scents or cleaners

- Hand soaps

- Face cleansers

- Suntan lotions

- Moisturisers

- Metal restorers.

Build Your Own Trigger Pump

Raepak offers a ‘build your own’ trigger pump service. This gives the brand owner more control over the final design. Custom changes include trigger options, nozzle options and collar options.

Can you tell me about any company who sell spray pumps with different components?

Hello! Samima,

Please get in touch with one of our team members so we can talk about what type of spray pump you need for your products.

Good day,

I’m urgently looking for the tubing used with a trigger spray pump. It is for quite a large number of sprays and the OD is 3.8mm, lenght 270mm.

Hello Jacques,

Thanks for getting in touch. We can cut tubing for trigger pumps to the desired length. Please get in touch with one of our account managers.

Hello,

I am planning to start my own business and I wanted it to be the manufacturing and production of trigger sprayer, right know I am in gathering information step, I contacted some supplier of spray cap molding machine and assembly machine, they inform me that I should send them a design of the product I need, I have an idea how the trigger sprayer work and its parts however I have no technical design of the parts, so could you help me and it would be a great pleasure if you can help me and why not start my business with you.

Hello Mondher, Please contact one of the team members so we can help you further with this request.

Can we buy the design from you as a 3d model?

All our designs are copyright protected but you can buy the product.

What is meant by

28/400

28/410

20/410

24/410.

is it height and width?

Hello Jennifer, Thanks for getting in touch. This is a good question. 28 would be the height and the 400 is the width. You can use these measurements to pick the correct bottle so both products match up.

are the measurements in mm?

Hello Shakerah Olivera,

Yes! We tend to measure in mm.

Hello,

Could you give me an estimation of how much does it coast a full line production of trigger sprayer, I have some money and I want to start a new business, if the line is affordabal, I can start my business with you. Thank you in advance

Hello Mondher, we would love to help you get your business off the ground. Please speak to one of our friendly account managers for an estimate on price.

How can I know the best plastic mesh specification?

Hello Erika,

Thanks for your question. We test many of our trigger sprayers through the manufacturing process. We make sure the best mesh specifications are best suited for the durability of the product life span.

I am looking for a quiet trigger sprayer to use on livestock. It needs to be adjustable, for misting or a stream.

Do you have any suggestions, I am unable to find any at this time.

Hello Lana,

Why not get in touch with our friendly account managers, we should be able to put something together for you. We can provide you with samples to test.

Is it possible to get a trigger pump that doesn’t contain PP so it can be used with HOCl without degrading it?

Hello Ken,

Anything is possible when it comes to manufacturing. However, you would need to develop a new tool and test the different types of plastic to make sure it works. This is timely and a very costly procedure. We have been working on fully recyclable dispensing pumps but we haven’t developed a trigger pump option yet.

Hello! Raepak, I was looking into a trigger pump option which can dispense gels as droplets. Do you have such a creation?

Hello! Markandeya, thanks for your lovely question. We would have to have a look at your product and test a few variables. We would need to look at the viscosity and the bottle being used to store the liquid. We would then test your product with our range of different trigger pump option to see which product would work best for dispensing the gel. Testing is key as the result may be different depending on the liquid solution you sign off as your product.

Hi Phil,

What is the typical maximum pressure buildup in a trigger sprayer? Thanks!

Hi Michael, Thanks for the great question. We think it could be around < 0.5 kg of pressure or 1.1 pounds per square inch. Hope this helps.

Hello,

I have recently obtained a stash of old, hand blown glass bottles with cork closures. I want to reuse them as a container for a spray cleaner, however I don’t know if this can be done as all of the sprayer inserts I have found have threaded closures. These won’t work on these old bottles as there are no threads on the bottles to weave the cap into.

Do you know if a ‘cork insert’ sprayer like that does exist and, if so, where I can purchase it?

Thank you!

Hello Katie Wright,

We might be able to help with a lick on dispensing sprayer. Please get in touch with one of our Account Manager for further information.

Which are the most common filter problems and solutions concerning “Trigger Sprayer 28/400”?

Thanks for the guide received to my e-mail.

In spite of this, we need to have some further and technical explanation of why “dip tube shalf” piece could have filter problems and what solutions should be given?

Hello Andres, thanks for your comment. We will look at completing a guid on this.

Ok. Thanks. We could also deliver some pictures (filtering problem) if required for best visual analysis from your side.

Please send e-mail for delivery.

I am wondering why sprayer can’t be made of a material other than plastic? I’ve looked at multiple articles, such as yours, that explains the history and function of the sprayer but none point out why it can’t be made of metal or some other material. As a manufacturer, I imagine you are the most informed about why this isn’t possible.

Hello K.

Thanks for getting in touch. You can potentially make a spray pump out of any material, including cardboard or metal. Plastic is easy to mould, cheap to produce, works with most liquids, can be recycled and is easy to colour match. We can also create some really lovely designs with plastic. Metal would rust, be expensive to mould – transport – source and produce. Other alternative materials come with a wide range of problems. I hope this helps with your question?

Hi,

Is it common for trigger pumps to leak (minor leak of few drops of liquid) when stored in an inverted condition for a prolonged duration (12-24 hours). I find this in about 5-6% of the bottles. The leak is from the trigger area (same spot from where air vent leakage happens during inverted actuation of trigger).

Please help.

Thanks

Indranath

Hello Indranath,

Thanks for getting in touch. Yes! There could be a possible leak if the trigger pump is stored upside down. There may be liquid still in the tube and pressure from the outside of the bottle, the effect of gravity and small amounts of pressure from inside the bottle could cause a small amount of leakage. Some trigger spray pumps have an OFF/ON safety switch that can eliminate this small leakage.

how long does the trigger sprayer last?

Hello Dan,

Great question. A trigger spray pump can actually last a lifetime. However, this does depend on how you are using the trigger pump. Let’s say 1 million presses for good measure.

Bonsoir Madame, Monsieur,

Mon camarade et moi sommes élèves de prépa scientifique physique-chimie. Nous faisons notre Travail d’Initiative Personnelle Encadrée (TIPE) sur le pulvérisateur à gâchette et plus précisément sur ce produit. Notre but et de comprendre comment s’effectue le déplacement du fluide à l’intérieur du pulvérisateur. Or, nous rencontrons des difficultés dans nos calculs de mécanique des fluides quand nous essayons de déterminer la vitesse du fluide en sortie de pulvérisateur. Nous vous demandons donc de nous éclairer quand au fonctionnement de votre produit.

Nous espérons pouvoir converser en français avec vous. En espérant avoir suite à ce message,

Cordialement,

Antoine et Luc

Bonjour Antoine & Luc

Merci de m’avoir contacté. “Cependant, nous rencontrons des difficultés dans nos calculs de mécanique des fluides lorsque nous essayons de déterminer la vitesse du fluide sortant du pulvérisateur” La vitesse du fluide sortant du récipient sera déterminée par la pression appliquée par l’utilisateur. En appuyant fort ou doucement sur la gâchette du pulvérisateur, on obtient la variable finale de pression pour la sortie. Vous aurez besoin d’un capteur de pression pour calculer le poids de la pression pour différents calculs.

J’espère que ça aide.

English –

Hello Antoine & Luc

Thanks for getting in touch. “However, we encounter difficulties in our calculations of fluid mechanics when we try to determine the speed of the fluid leaving the sprayer” The speed of the fluid leaving the container will be determined by the applied pressure from the user. By pressing the trigger sprayer hard or softly, gives the final variable of pressure for the output. You will need a pressure sensor to work out the weight of pressure for different calculations.

I hope this helps.

Bonsoir Monsieur,

Merci pour votre réponse. Cependant, nous avons déterminé la force minimale qu’il faut exercer sur la gâchette pour que celle-ci s’enfonce complétement : 21 Newton environ. Mais il faut prendre en compte la résistance du ressort blanc visible de part et d’autre du piston, les frottements de contact plastique-plastique et les frottements du liquide sur les parois en plastiques (peut-être devrions-nous parler de l’écoulement de Poiseuille), ce qui rend les calculs tout de suite plus compliqués. On a déjà obtenu la vitesse de translation du piston lors d’un appui sur la gâchette pour une force appliquée de 24,5 Newton. Pouvez-vous nous éclairer un peu plus svp ?

Merci d’avance,

Antoine et Luc

Hi, I am a high school student doing a reverse engineering project on a sprayer pump. I am interested to know if you can provide me an estimate of the cost of individual parts and/or assemblies. Thank you for any help.

Hello Elias,

Thanks for getting in touch and we hope your reverse engineering project is going well. With regards to the cost of every single part that makes up a trigger pump. It seems an impossible task for us. The reason is: as we are a distribution company and buy the trigger pumps as a single unit, we don’t have price points for each component. However, for a single unit, the price can range from 39p to 89p on average.

We hope this information helps you with your project.

Hello,

I am looking into new materials to use in our company. Can you give me a few suggestions for trigger spray injection moulding materials. (PP Granules)

Hello Gokhan, thanks for getting in touch with our packaging team. Trigger sprays are normally used with a range of different plastic materials. We call these composite plastic. However, a manufacturer may be able to produce a trigger pump spray with HDPE, PP, PET or PCR plastic materials. We hope this helps.